DuPont Aristri P5000+ ink Pre-treatment Solution

Aim

In order to achieve consistent and even white prints on dark or light colored cotton fabrics, proper application of the pre-treatment solution must be practiced. Proper application of the pre-treatment solution is key to obtaining optimum white opacity and ink adhesion to the fabric.DuPontTM Artistri® P5001 and P5002 are fabric pre-treatment products for application onto dark colored cotton t-shirts that enable clean and consistent printing with DuPontTM Artistri® P5910 and P3590 white ink. The advantages of using DuPont pre-treatment with DuPontTM Artistri® ink are:

- Outstanding white ink opacity on dark colored cotton garments

- Fewer printed t-shirt defects

- Less sensitivity to fading due to UV Exposure

- Reduced post-pressing shine

DuPont P5001 and P5002 pre-treatment solutions are for use only with DuPontTM Artistri® P5910 and P3590 white ink.

Safety

This product can be used safely when used as directed and when applicable safety precautions are followed. Please refer to the supplied MSDS sheet prior to use of this product.Adequate ventilation must be provided when using this product. This should be achieved by a good general extraction and - if practically feasible - by the use of a local exhaust ventilation. If these are not sufficient to maintain concentrations of particulates and solvent vapour below the OEL, suitable respiratory protection must be worn. An N95 Approved Respirator (3MTM Model # 8210 or similar) is recommended where adequate ventilation is not possible. For more information on ventilation, please refer to the MSDS document EU_en_6200-109214_INK.

It is also recommended that operators wear appropriate hand and eye protection when using this product. Again, please refer to the product MSDS for guidance.

Application of Pre-treatment

DuPontTM Artistri® P5001 and P5002 pre-treatment can be applied manually using a hand sprayer or mechanically by the use an automatic pre-treatment unit. Automatic pre-treatment applicators are available from a number of printer and silk screen suppliers. An automatic pre-treatment unit offers a number of advantages, not the least of which is a consistent and repeatable application of pre-treatment to the garment. However, DuPontTM P5001 and P5002 can be easily applied through a manual hand sprayer without loss in quality. Detailed instructions for application with a manual hand sprayer are provided below. If you choose to use an automatic pre-treatment machine, please refer to your vendor's usage instructions for proper safety and use.

Measuring Pre-treatment Application

Regardless of whether you use an automatic unit or a hand sprayer, the recommended amount of pre-treat to use on a 14"x17" print area is between 20g and 25g (0.7 oz to 0.9 oz). Some automatic pre-treat machines allow you to specify a spray volume - if you are using one of these machines please refer to the manufacturer's instructions to dial in the correct amount of pre-treatment. In other cases, the procedure below is good way to determine whether you are applying a correct amount of pre-treatment.- 1. Using a scale that is accurate to at least 1 gram, weigh an un-treated shirt.

- 2. If your scale has a "Zero" option, zero the scale on the shirt weight. If not, note the shirt weight.

- 3. Pre-treat the shirt (manual or automatic). An automatic unit should have a setting that is normal – use that as a starting point. In the case of manual application, use the procedure provided below.

- 4. Immediately weigh the pre-treated shirt. Weigh the shirt wet, DO NOT PRESS THE SHIRT OR DRY BEFORE WEIGHING. If you zeroed the un-treated shirt, the weight should between 20g and 25g. If you simply noted the weight of the un-treated shirt, the wet shirt should be 20g – 25g heavier than the untreated shirt.

- 5. If the weight was either heavier or lighter than desired, adjust your pre-treatment application and re-run the test.

This is not a procedure you will need to run every time you prepare shirts; it is simply a set up procedure. Once you have determined the right amount of pretreatment, it is fairly simple to continue to pre-treat consistently and correctly apply pre-treatment whether you are using an automatic unit or hand sprayer. In the rare cases where your shirts are not printing or washing correctly, refer to the troubleshooting section below.

Equipment Needed for Proper P5001 or P5002 Pre-treatment Application:

- N95 Approved Respirator (3MTM Model # 8210 or similar)

- Foam Roller (the type used for painting)

- Liquid Applicator (airbrush, air pump sprayer, fine mist power sprayer, such as Wagner® Power Sprayer Model HVLP)

- Heat Press. Most screen print suppliers offer heat presses, see your supplier for their recommendation..

- Non-Silicone Parchment Paper or Teflon sheet

Recommended Procedure for Manual Application:

The following procedure will help ensure consistent quality and performance of the DuPontTM Artistri® P5910 and P3590 white ink:- 1. Agitate or shake the pre-treatment solution prior to filling your sprayer. Locate the sprayer area in a different room than your printer(s). Overspray can find its way into the printer and potentially damage the device.

- 2. Locate the sprayer area in a well-ventilated area. Set the heat press for 170oC. If you do not have adequate ventilation, use an approved respirator when spraying the pre-treatment. Please the Product MSDS.

- 3. In humid environments, it is often beneficial to pre-press the shirt (using the parchment paper or Teflon sheet as a barrier from the press) for 10 to 15 seconds prior to applying the pretreatment. This removes some of the water naturally trapped in the fibers which can cause printing defects..

- 4. Using the spraying system, spray P5001 or P5002 pre-treatment solution evenly on the area that is to be printed. The recommended coverage is about 20g to 25g (0.7 oz to 0.9 oz) for a 14" x 17" printing area.

- 5. The hand sprayer should be set up as follows:

Set your sprayer for medium coverage. This is normally the setting between no liquid being sprayed and the maximum available.

Prime the sprayer for a few seconds by spraying into a large cup, but not on to the shirt area. This helps prevent larger drops that occur when the sprayer is starting up.

Keep the sprayer about 12 inches (0.3 meters) from the shirt and begin spraying from the top to the bottom in a left to right (and then reverse, right to left) motion without ever turning off the sprayer

If all settings are correct, you should dispense the proper amount of pretreatment solution in about 15 seconds.

It is good practice to allow the sprayer to go beyond the edges of the shirt before beginning or reversing direction. This prevents more pretreatment from being deposited on the shirt during the direction change. - 6. After spraying the garment, wipe with the foam roller, uniformly and in one direction, to get even coverage.

- 7. Dry the pretreated garment with the heat press (using the parchment paper or Teflon sheet as a barrier from the press) a minimum of 15 seconds, up to a maximum of 60 seconds at the 170oC (�oF) setting.

Your shirt is now ready to print.

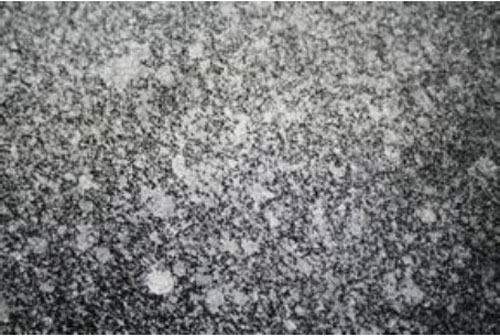

Correct Pre-treatment

The image below represents a shirt that has been properly pre-treated, printed, heat-pressed and subsequently washed through three (3) industrial washes. Note the white underbase and color retention.This is a properly treated, printed and post-treated shirt.

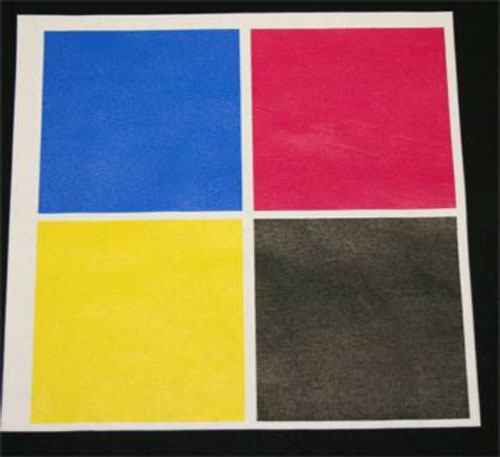

Insufficient Pre-treatment

If too little pre-treatment solution is applied, the white ink will have a mottled appearance after printing. This is due to an insufficient amount of pre-treatment to keep the white ink layer on the surface (the ink soaks into the fibers of the shirt).An example of insufficient pre-treatment:

Excessive Pre-treatment

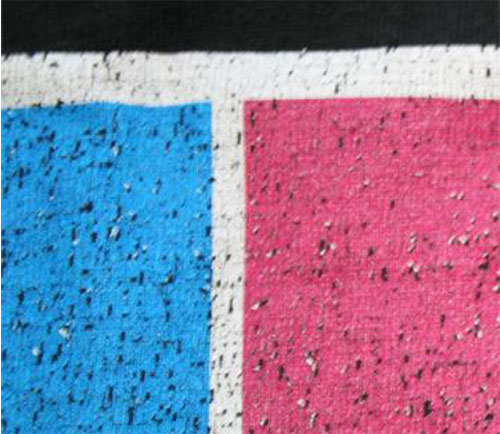

Applying too much pre-treatment solution will provide you with a very good looking print prior to washing. However, excessive application of pre-treatment will cause poor wash fastness and durability. The white layer becomes much more susceptible to flaking off of the shirt in a wash if too much pre-treatment is applied.Below, the shirt with an excessive amount of pre-treatment looks very good after printing and pressing:

The same shirt, with excessive pre-treatment solution applied is shown below after washing. This shirt exhibits cracking and loss of color associated with too much pre-treatment being applied.

Quick Contact / RFQ

- Contact: DONGLAO Village Road No.76 Fengtai District,Beijing 100070 China. Phone: 86+10+63717786 email: info@dtgjet.com

- Copyright © 2005-2013 Dtgjet All Rights Reserved

- Friendly link:Phone cover printer | Brotherjet | Pradocam cnc engraver